Create the Way of the Future with AR VR in

Chemical Industry

Create the Way of the Future with

AR VR in Chemical Industry

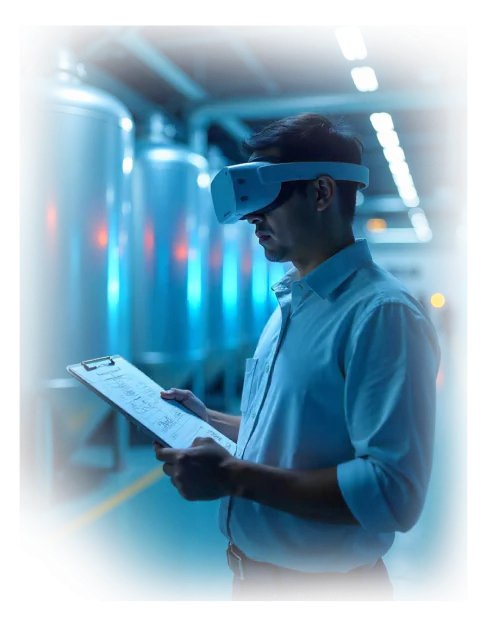

Transforming the Chemical Industry with

AR VR Solutions

The chemical industry is complex and multifaceted, requiring precision and robust safety measures.

Rampant errors, improper maintenance, and unplanned downtime can affect a company’s operational efficiency

and financial health and ultimately impact its employees and customers.

To remain competitive, companies need to operate safely and reliably, a highly trained and skilled

workforce is required. Deploying cutting-edge technologies such as AR/VR can revolutionize how chemical

companies operate, innovate and succeed.

Our AR VR Solutions for Chemical Industry

Augmented Reality can deliver immersive and scenario-based experiential learning, enabling engineers and technicians to learn critical skills, test, and evaluate themselves in a zero-consequence and risk-free virtual environment.

AR-assisted Learning

AR overlays digital information onto the physical environment, providing step-by-step guidance and real-time data, which helps understand complex procedures, and machinery operations to gain hands-on learning experience in a safe and controlled environment.

Safety Protocols

Technicians can use AR glasses and devices to receive real-time alerts and instructions, ensuring compliance with safety regulations, situational awareness, and reducing the likelihood of accidents.

Plant Design and Review

VR allows engineers to virtually walk through and interact with 3D models of chemical plants and identify any potential issues before physical construction begins.

Process Visualization

Maintenance personnel can see real-time data on complex chemical processes such as temperature, pressure, and flow rates in a virtual environment. This allows better process monitoring, identification of potential issues, and proactive maintenance strategies.

Complex Data Exploration

AR VR in Chemical industry can visualize and interact with complex data sets in 3D allowing chemists to virtually immerse in a 3D representation of molecular structures or reaction pathways for deeper analysis, resulting in accelerated scientific discovery.

Leverage the Benefits of

AR VR in the

Chemical Industry

AR/VR can enhance safety training, optimize production processes, and improve equipment maintenance in the chemical industry, enabling immersive simulations and real-time problem-solving techniques.

Why Novac Immerz?

Leveraging AR/VR technology within the Chemical industry can enhance various aspects, including customer experiences, operational efficiency, and innovation. With Novac Immerz, your business can grow and gain a significant competitive advantage in the chemical landscape.

Why Novac Immerz?

Leveraging AR/VR technology within the Chemical industry can enhance various aspects, including customer experiences, operational efficiency, and innovation. With Novac Immerz, your business can grow and gain a significant competitive advantage in the chemical landscape.

Measurable Insights

As every user action is recorded using immersive technologies, insights and assessments to drive measurable outcomes and enhance business processes are easy to access.

Enhanced Engagement

A fully interactive, immersive platform experience allows employees to train in a safe environment, reinforcing the correct behavior pattern and knowledge retention for various chemical incident scenarios.

Curating the Best Technology and Solutions for You

100+

Projects

50+

Clients

50+

Industry Experts

Ready to transform the foundations of the Chemical Industry?

Tech Stack

Tech Stack

Leaders Who Trust Us

Leaders Who Trust Us

Testimonials

Anand Megalingam

CEO, Space Zone IndiaWe, from Space Zone India have tasked Novac to develop Virtual Reality projects in Rocket and Drone Technology. They delivered outstanding results within an impressive 20-day timeframe, with impeccable quality of work, surpassing our expectations. Their supportive team was always available to address queries and resolve any issues promptly. This unwavering dedication to excellence stands as a testament about their exemplary service and commitment to client satisfaction.

Gowtham Kumar

Product Manager, Pidilite Industries LimitedSince July-August 2023, we have been deploying the services of Novac for our Web-based AR application. One of the key positives is their quick response to feedback, ensuring our needs were met promptly and efficiently. They consistently delivered within the committed timelines, which is crucial for our projects. We laud their exceptional support and professionalism throughout the implementation process, which made us an automatic loyal customer.

Ready to Upscale Your Industry?

Fill out the form, and we’ll be in touch with you as soon as possible. Our team is happy to answer all your queries.

Call Us

044 42913000Get In Touch

info@novacimmerz.comSimply fill out the form, and we’ll be in touch.

Frequently Asked Questions

Modern AR and VR solutions are designed to be intuitive and user-friendly, with interfaces that can be easily navigated even by those with limited technical expertise. Additionally, comprehensive training programs are provided to ensure that all employees can effectively utilize these immersive technologies.

The initial investment in AR and VR technology can vary depending on the complexity and the scale of deployment. However, the long-term benefits, such as improved workplace safety, enhanced training efficiency, reduced downtime, and better operational efficiency, often outweigh the upfront costs.

AR and VR systems require regular updates and maintenance to ensure optimal performance. This includes software updates, hardware maintenance, and occasional calibration of sensors and devices. Most immersive solution providers offer comprehensive support packages to assist with these tasks.

Evaluating the ROI involves assessing the costs of technology acquisition and implementation against the benefits, such as improved industrial safety, reduced downtime, increased operational efficiency, and enhanced training outcomes. Tracking key performance indicators (KPIs) before and after implementation can help measure the impact of AR and VR implementation.